- Home

- Products

- EAA / Ionomer

- Primacor

EAA / Ionomer

Primacor

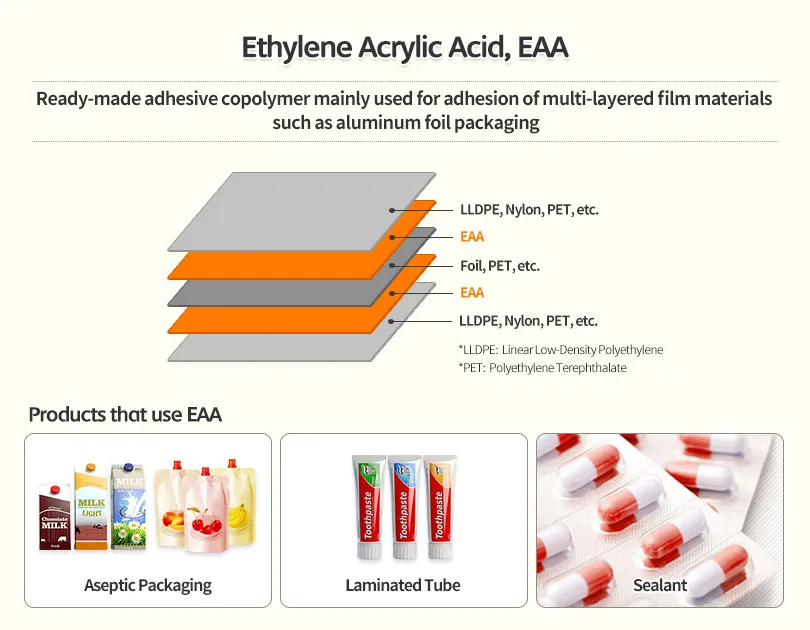

EAA CopolymersDescription

EAA Tie two incompatible layers together

PRIMACOR ™ EAA copolymers offer excellent performance and processability for extrusion coating, blown and cast film and eco-friendly aqueous dispersion application.

This EAA (Ethylene Acrylic Acid) material also offers excellent hot tack and adhesion to metallic, paper, polyolefins, and other polar substrates with her unique carboxyl branch which can strong hydrogen bond with each other ; exceptional resistance to most oils, greases, acids, and salts ; non-hygroscopic/hydrophilic performance ; dispensable heat sealing ‘ and excellent puncture, tear, abrasion, and stress crack resistance.

High acid contents, High melt Index PRIMACOR ™ EAA has developed and suitable for aqueous dispersion without salts, surfactants or solvent in high solid concentrations, then lead to make extremely thin but strong tie or coating to substrates ; minimum use of adhesive material but strong bonding force ; recyclable / compostable of coated paper packaging ; strong adhesion of various materials in EV battery ; transparent and protective coating to expose raw substrates.

Application

Intermediate Raw Materials, Construction Coating, Fertilizer, Industrial Film, Home Appliance Exterior, Wire & Cable, Household Goods, Pharmaceutical Packaging, Flexible Packaging, Tie Resin, Paint & Ink, Primer, Paper Coating, Film & Plastic Coating

| Grade | Acid Contents | Melt Index (g/10min) | Density (g/cm3) | Tm (°C) | Vicat (°C) | Important Physical Properties | Application Example |

| ASTM D1238 | ASTM D792 | ASTM D4094 | ASTM D1525 | ||||

| Film Application | |||||||

| 1321 | 6.5 | 2.50 | 0.935 | 103.0 | 88.9 | Good interlayer adhesion to PE, PA Good optical properties Excellent toughness and strength Excellent environmental stress crack and product resistance Good hot-tack and sealability Insensitivity to moisture |

Food & beverage Packaging Wire & cable Medical packaging Compounding |

| 1410 | 9.7 | 1.50 | 0.938 | 97.8 | 81.1 | Excellent hot tack and sealability Excellent toughness and strength Excellent crack resistance Insensitivity to moisture | Food & beverage packaging Industrial film Compounding |

| 1430 | 9.7 | 5.00 | 0.93 | 96.1 | 76.1 | Adhesive layer of sealant layer in flexible packaging structures For blown or cast film extrusion Used where adhesion to nylon or foil is desired |

Food & beverage packaging Industrial film Pipe coating |

| Extrusion Coating Application | |||||||

| 0698 | 3.0 | 7.50 | 0.927 | 105.0 | 96.0 | Good adhesion to metallic, paper and polyethylene substrates Good heat sealability and hot-tack Excellent draw-down Low neck-in Compatible to PE |

Food & beverage packaging Wire & Cable Medical packaging |

| 3002 | 8.0 | 9.80 | 0.936 | 100.0 | 82.2 | Excellent draw-down and edge stability Excellent organoleptic properties Excellent toughness and strength Outstanding environmental stress crack and product resistance Excellent hot-tack and sealability Adhesion to paper, paperboard, metals and polyethylenes Insensitivity to moisture |

Tea bags packaging |

| 3003 | 6.5 | 7.80 | 0.935 | 100.0 | 90.0 | Excellent draw-down and edge stability Excellent organoleptic properties Excellent toughness and strength Outstanding environmental stress crack and product resistance Excellent hot-tack and sealability Adhesion to paper, paperboard, metals and polyethylenes Insensitivity to moisture |

Food & beverage packaging Laminate tube |

| 3004 | 9.7 | 8.50 | 0.938 | 98.0 | 81.1 | Excellent draw-down and edge stability Adhesion to paper, paperboard, metals and polyethylenes High performance sealant or tie layer Excellent hot-tack and sealability Excellent seal through contamination Excellent product resistance Excellent toughness and strength Outstanding environmental stress crack and product resistance |

Food & beverage packaging Wire & Cable |

| 3150 | 3.0 | 11.00 | 0.924 | 104.0 | 88.9 | Excellent adhesion to paper, paperboard, metals and polyethylenes Good heat sealability Good draw-down Excellent oil and grease resistance Insensitivity to moisture |

Food & beverage packaging Wire & Cable Medical packaging |

| 3330 | 6.5 | 5.80 | 0.932 | 100.0 | 85.0 | Excellent adhesion to paper, paperboard, metals and polyethylenes Excellent hot-tack and sealability Excellent toughness Excellent oil and grease resistance Insensitivity to moisture Low odor |

Industrial film Wire & cable Protective film Pipe coating |

| 3340 | 6.5 | 8.60 | 0.932 | 101.0 | 83.9 | Excellent adhesion to paper, paperboard, metals and polyethylenes Excellent hot-tack and sealability Good oil and grease resistance Insensitivity to moisture |

Food & beverage packaging |

| 3440 | 9.7 | 10.00 | 0.938 | 97.8 | 81.1 | Excellent adhesion to paper, paperboard, metals and polyethylenes Excellent hot-tack and sealability Excellent toughness Excellent stress crack resistance Insensitivity to moisture Designed specifically for high line speeds |

Food & beverage packaging Tea bags Packaging Wire & cable Medical packaging Laminated tube Compounding Powder coating |

| 3460 | 9.7 | 20.00 | 0.938 | 95.0 | 72.2 | Excellent heat sealability, hot tack Excellent adhesion to metallic, paper and polyethylene substrates Good stress crack resistance Designed specifically for high line speeds and low processing temperature Insensitive to moisture |

Food & beverage packaging Powder coating Paper coating Compounding |

| 3540 | 8.5 | 7.00 | 0.936 | 99.4 | 85.0 | Excellent adhesion to metals, polyethylenes, and papers Excellent toughness Excellent stress crack resistance Extrusion coating & lamination adhesive polymer Enhanced adhesion retention Low neck-in |

Aseptic packaging |

| 4608 | 6.5 | 7.80 | 0.934 | 98.9 | 86.1 | Excellent heat sealability and hot tack Excellent adhesion to metallic, paper and polyethylene substrates Excellent draw down Good oil and grease resistance Insensitivity to moisture |

Food & beverage packaging Aseptic packaging |

| Dispersion Application | |||||||

| 4810 | 14.5 | 55.00 | 0.945 | 90.5 | 60.0 | Dispersible in aqueous media Dispersions use existing waterborne application equipment Low heat seal temperature, high hot tack Excellent grease and oil resistance, water hold-out and excellent product resistance for flexible packaging applications Low odor |

Paper coating Pre coated metal Powder coating |

| 5980I | 20.5 | 300.00 | 0.958 | 77.2 | 42.2 | Dispersible in aqueous media “Clean” dispersion requires no salts, surfactants or solvents Dispersions use existing waterborne application equipment Low heat seal temperature, high hot tack High gloss, excellent clarity Excellent grease and oil resistance, water hold-out and excellent product resistance for flexible packaging applications |

Food & beverage packaging Paper coating Pre coated metal Ink and paint Additives Powder coating |

| 5995 | 20.7 | 1460.00 | 0.955 | 75.0 | 40.0 | Dispersible in aqueous media with high solid contents “Clean” dispersion requires no salts, surfactants or solvents Dispersions use existing waterborne application equipment Low heat seal temperature, high hot tack High gloss, excellent clarity Excellent water, grease and oil resistance |

Food & beverage packaging Paper coating Pre coated metal Ink and paint Additives Powder coating Hot melts |